Boiler House, Sheffield

Overview

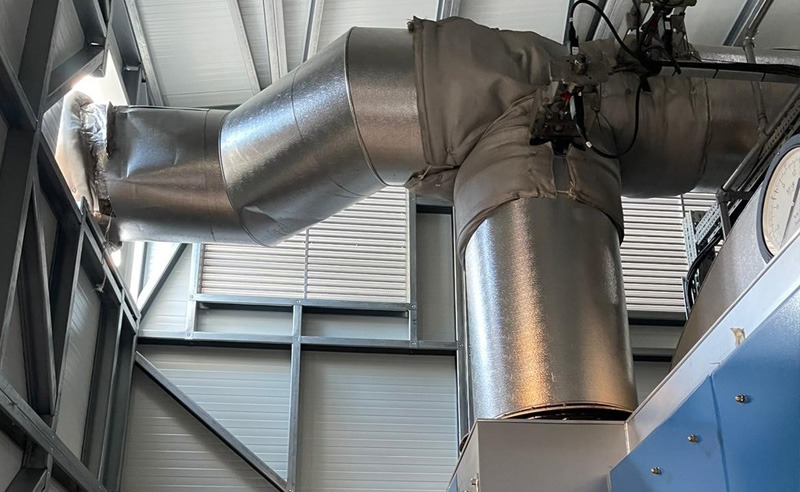

We worked closely with the heating engineering company who were contracted to carryout a 12-month multi million-pound replacement of the factories existing heating/hotwater system. The new boiler was designed to re-cycle its exhaust gases and waste heat, resulting in reduced energy consumption and a more environmentally friendly system.

The brief was to initially design a building to house the large boiler that could have one side temporarily dismounted so that the boiler could be slid in on a sledge system once the building was erected. The dismounted wall would then be reinstated, but able to be dismounted again if required for maintenance/servicing purposes.

Unfortunately, due to the lack of suitable on-site storage capability, the boiler had to be positioned on the slab prior to the erection of the boiler. We then had to erect the building around the boiler together with all of its associated pipework in-situ.

This presented us with several potential installation problems quite late in the programme. However, by working with our installation team and the client’s engineers, a detailed workable proposal was devised. It resulted in a smooth, problem free installation which took just 4 days from start to finish. The boiler was then fully tested and commissioned the following week.

Building Spec

Structure Size:5m x 10m x 5.5m

Colour: Goosewing Grey BS10A05

Roof Type: Apex

Cladding: Horizontal Maxi Rib

Doors:2 x PA door and fire escape

Insulation Level: 40mm

Project Details

LOCATION

Sheffield

BUILDING TYPE

Boiler House

CLIENT

Food Production

DESIGNER

Hanson’s

START DATE

March 2022

HANDOVER

April 2022